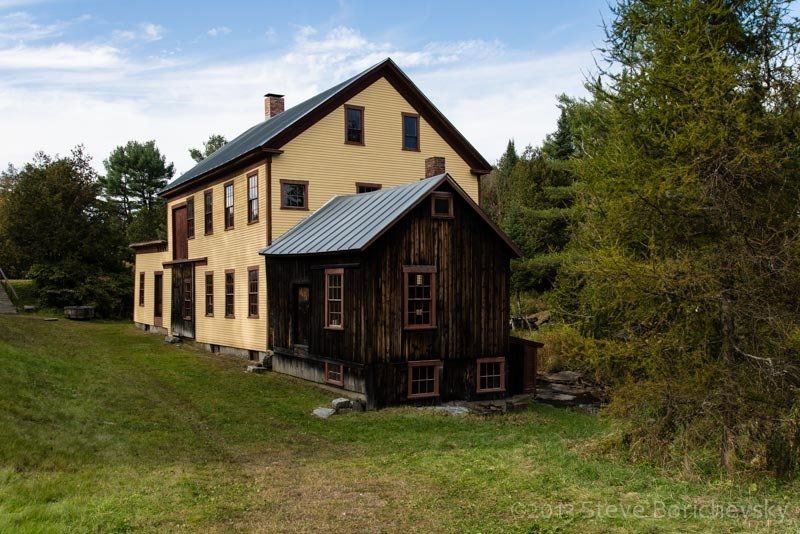

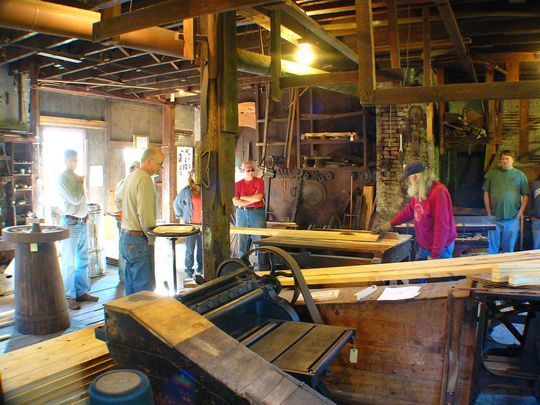

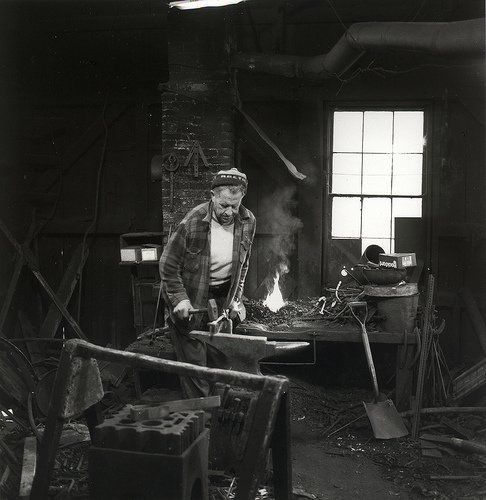

The planer at Ben's Mill was manufactured by C.M. Baxter, Lebanon, N.H. with a patent date of 1879. Fenton Judkins purchased the planer sometime between 1900 and 1938. This was the first machine that Eric Esser cleaned up and restored to working order.

Previous to power driven planers with rotary heads all wood stock was “milled” flat and to thickness by journeymen, carpenters, house joiners and furniture makers with hand-planes. The earliest recorded patent for a planer was granted in 1776 in England. The patent was merely for crude sketches that were never developed into a working machine. In 1791 and 1793 Sir Samuel Bentham, in England, received patents for the basic principles used in most wood-working machines, notably for rotary cutters.

The first actual wood planing machine was built by Malcolm Muir of Glasgow, Scotland in 1827. The planer's purpose was specifically for the milling of tongue and groove flooring. It included a cutter head to smooth both faces of the board and to run the tongue and groove joinery in the board's edges. State side a similar machine was invented and patented in 1828 by William “Uncle Billy” Woodworth. Woodworth's machine was described as “the combination of rotary cutters and feeding rollers and of rotary matching cutters so as to form a tongue and groove on both edges of the lumber at the same time that the principal surfaces are planed.” These first planing machines did not sit well with the carpenters as 24 hour security was required at the mills to protect the machine. Woodworth maintained the patent and a monopoly on the machines for 14 years.

Woodworth obtained a patent extension for another 7 years. He sold it to Samuel Schenck, John Gibson, and Samuel Pitts. Each man controlled machine manufacturing and sales in different sections of the country. John Gibson set up a manufacturing plant in Albany, N.Y. with a planing mill nearby where he could demonstrate the planer in operation.

In 1843 the patent was re-issued with the inclusion of a “small hold down roller.” At this point in history the carpenters started to embrace this new technology and the demand for planers increased.

In 1856 the original patent expired and was not to be extended. Between 1856 and 1866 many improvements were made to the planer. Remember, at this point the planer is still a machine with four rotary heads for producing tongue and groove flooring. A planer with one rotary head for simply surfacing wood did not emerge until 1860. The Gray and Wood's planer was a modification of the previous planers that allowed for just surfacing the faces of boards.

C.M. Baxter started his business career as a furniture manufacturer in Norwich and Woodstock, VT. In 1872 he moved to Lebanon, N.H. and switched to manufacturing wood working machinery. An 1884 census of Lebanon, N.H. lists him as a manufacturer of band saws, planers, and furnaces.

On May 10th, 1887 a fire billed in a New York Times article as “the most destructive fire that northern New Hampshire has ever know” swept through Lebanon, N.H. destroying eighty buildings including the Baxter Machine shop. After this C.M. Baxter traveled back and forth between Redlands, CA and Lebanon, N.H. Eventually he settled in Redlands, CA in 1892 as a rancher and making investments for eastern connections.

The information in the article was gathered from an excerpt from a 1920 edition of the William H. Field Company “Field's Wood Working Machinery Reference Book”, as posted on the Old Wood-Working Machinery web-site, the ASME web-site, The Redlands Historical Society web-site and the New York Times archives . Fall 2007 Newsletter, author Sally Fishburn